Project Description

Our client is a US-based metal fabrication expert. The organization has more than three decades of experience in structural steel, mild steel, stainless and aluminum metal fabricating. The fabrication capability range includes Sheet metal work, machine bases, ductwork, frameworks, structural conveyors systems, and several others. The organization professionals are highly skilled in offering complete fabrication solutions from concept to completion. Apart from fabrication, the client brings expertise in machining, assembly, and painting as well.

Requirement of Detailed Shop Drawing and Erection Drawings

The client contacted the Sivani Engineering Services (SES) team for a detailed erection drawing, shop drawing, and fabrication drawing. SES webpage and portfolio gave them a glimpse of our high-quality and dynamic fabrication drawing services. They came up with a tight project timeline and supported the team with structural design and architectural design drawings. The client requested deliverables, like connection design reports, erection drawings, and shop drawings in KISS file, NC1, DX files, and other fabrication-related details.

Challenge of Laborious Connection Design in a Tight Time Frame

Steel to concrete connection detailing is a tricky process. The detailing requires multiple methods to follow for designing different elements of a single connection. SES used software Idea Statica, hand calculations, technical guidelines, and approvals for anchor, baseplate, welds, and stiffeners designing. We deployed a highly experienced team, Tekla experts, structural engineers, and 3D modelers to speed the design work. The design process was structured and scheduled efficiently and effectively for SES to deliver the project with a short timeline of 60 days.

Our Series of Actions in Fabrication and Shop Drawing

Steel to concrete connection detailing is a tricky process. The detailing requires multiple methods to follow for designing different elements of a single connection. SES used software Idea Statica, hand calculations, technical guidelines, and approvals for anchor, baseplate, welds, and stiffeners designing. We deployed a highly experienced team, Tekla experts, structural engineers, and 3D modelers to speed the design work. The design process was structured and scheduled efficiently and effectively for SES to deliver the project with a short timeline of 60 days.

1. The data shared by the client, e.g., detailed architectural drawings, structural drawings, were carefully studied and analyzed by the project team. The information gathered was documented and issues clarified by the client.

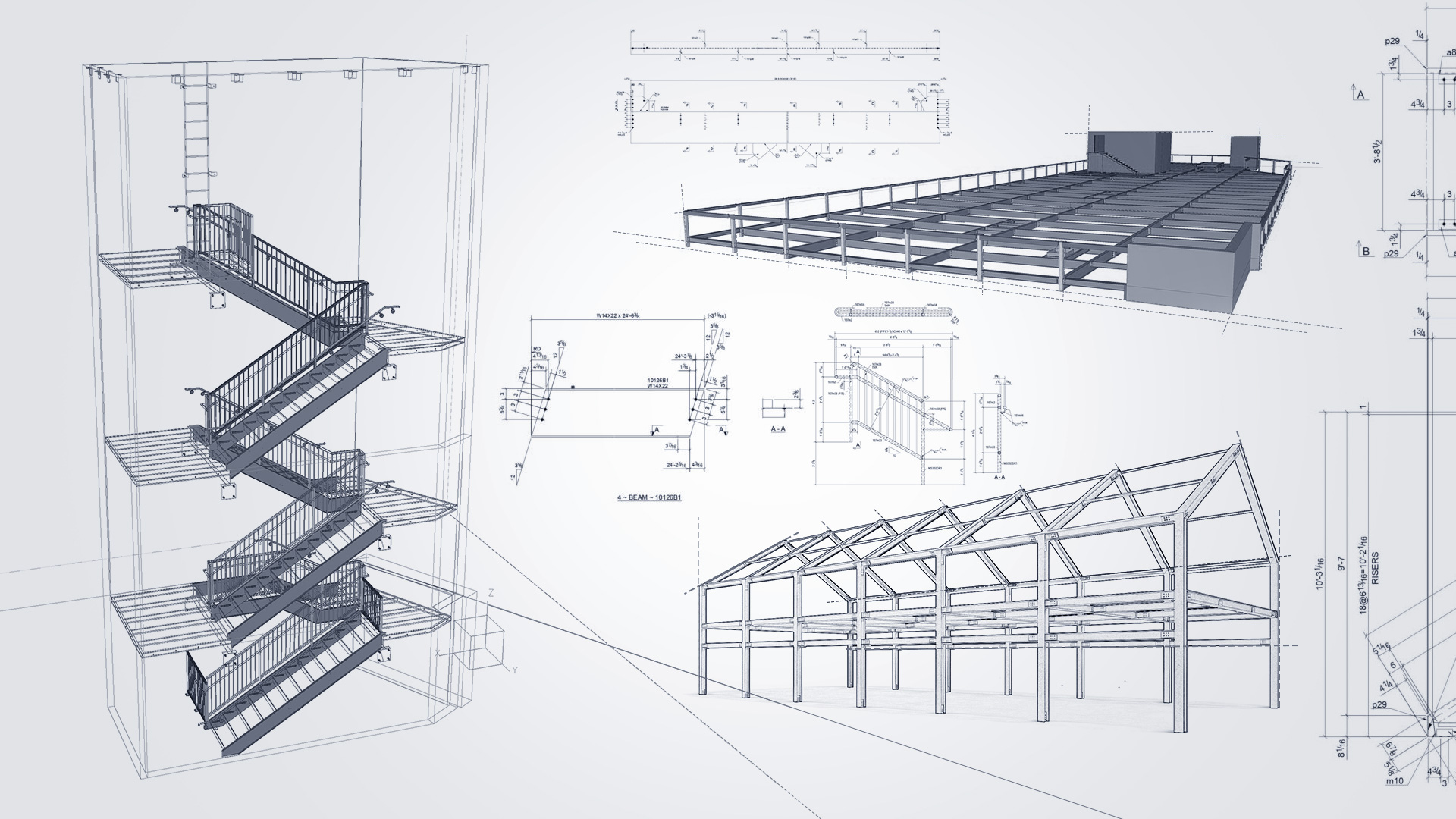

2. The team developed a 3D structural model using AutoCAD software based on the previous detailed study.

3. Our Tekla experts and steel detailers thoroughly analyzed the 3D structural model and developed the erection drawings. The drawing revealed the location and position of various assemblies.

4. We created shop drawings based on the data gathered by architectural and structural drawings. The designs complied the standards such as AISC, AWS, and OSHA.

5. All the drawings and documents went thorough quality check. We shared the drawings and reports with the client in the KISS file, NC1, and DXF files.

2. The team developed a 3D structural model using AutoCAD software based on the previous detailed study.

3. Our Tekla experts and steel detailers thoroughly analyzed the 3D structural model and developed the erection drawings. The drawing revealed the location and position of various assemblies.

4. We created shop drawings based on the data gathered by architectural and structural drawings. The designs complied the standards such as AISC, AWS, and OSHA.

5. All the drawings and documents went thorough quality check. We shared the drawings and reports with the client in the KISS file, NC1, and DXF files.

Project Takeaway for the Client – In line with Expectations

Steel detailing is a safety-critical task, requiring a high level of accuracy and coordination. SES developed highly-detailed connections designs, erection drawings, and shop drawings that enabled the client to meet their project requirement. The client was pleased with our high-detailing and adherence to the timeline. The team at SES enjoy handling complex and challenging task to nurture themselves. Get in touch with the SES team for detailed and comprehensive steel detailing drawings.